Cano, Bogaerts, New Balance customizing U.S.-made baseball cleats

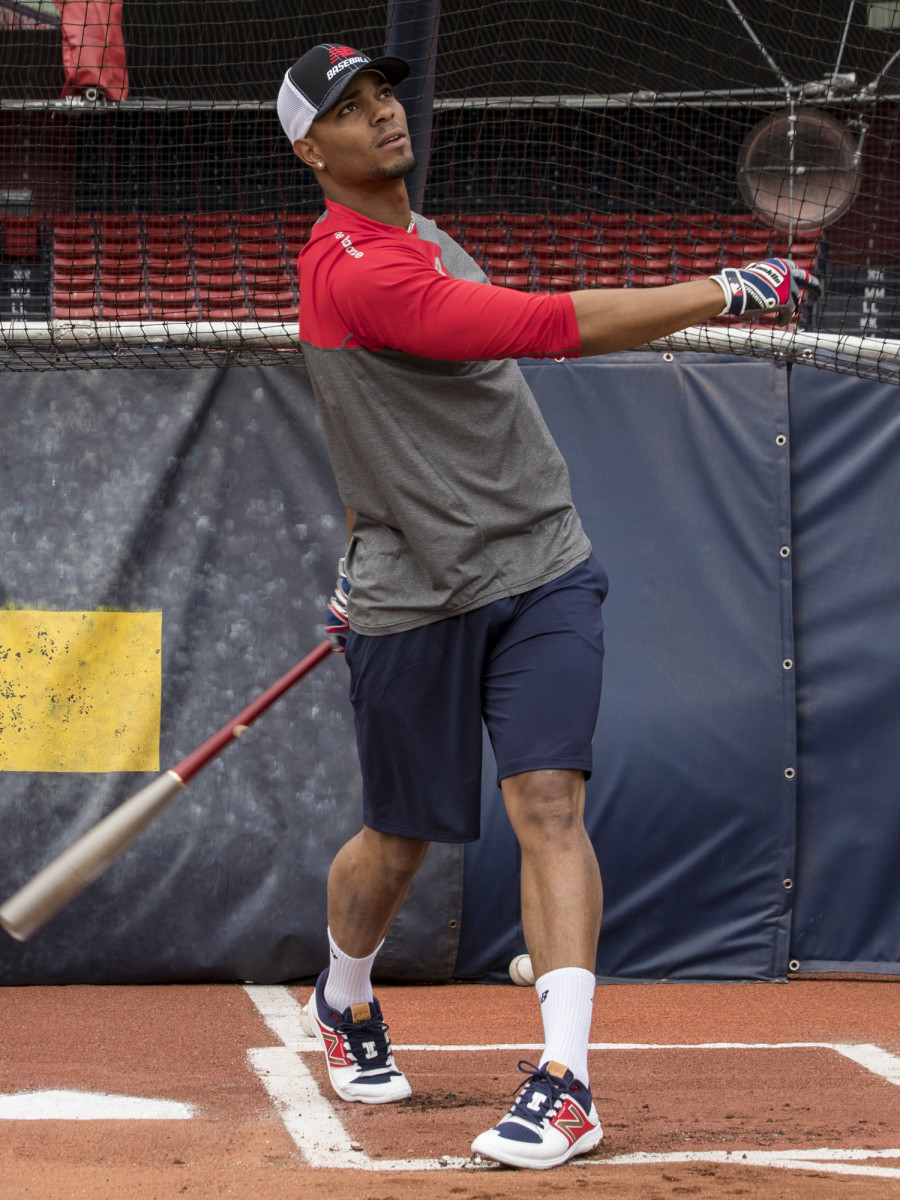

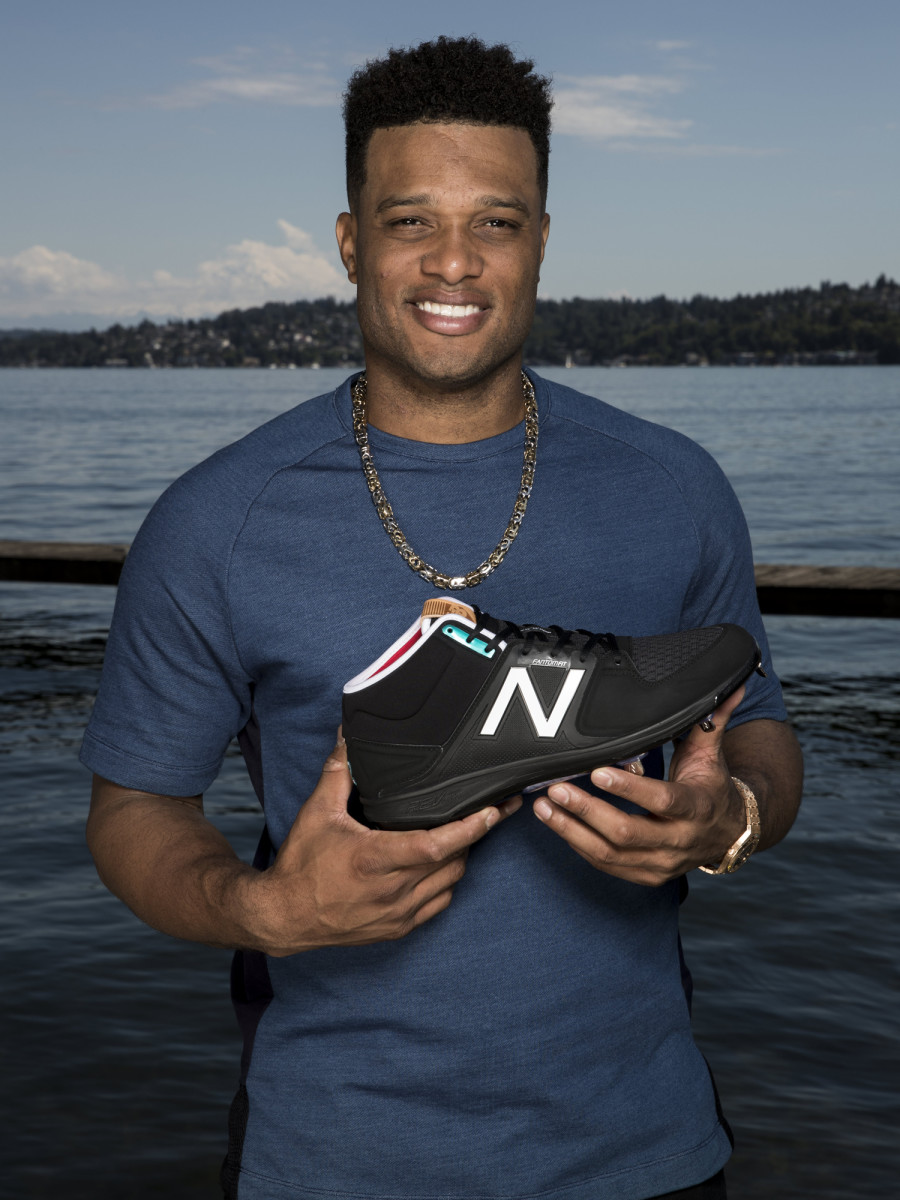

New Balance debuted the new 3000v3 baseball cleat—worn by Robinson Cano and XanderBogaerts—in August and less than a month later the two were showing off custom designs, part of the Boston-based company’s foray into building custom baseball cleats made in the U.S.

While not the first company to customize cleats for the general public via its NB1 website, by hand making all pairs at its facility in Lawrence, Massachusetts, the company can turn around the cleats in less than two weeks instead of the typical four or six-week process. But it took longer than that to figure out the best way to build the customization process, Jonathan Grondin, New Balance design manager, tells SI.com.

“In a lot of ways we were trying to make things all over again to build it in America,” he says. “We had to build our own machines and designers had to figure out what colors you need, what is available. Every time you give a new color, it is another shelf to build (on the manufacturing floor).”

To kick off customization of the new cleat, New Balance created a variety of choices for Cano and Bogaerts as examples of the billions of color combinations on a cleat known for a comfort collar and cushioning. “Xander does not have a custom, so he is super pumped,” Grondin says. “Xander almost felt like a little kid. The Red Sox having red and blue in the shoe makes multiple colors much more fun to do. The shoe he wore at launch, no one is wearing those color combinations.”

Going back-and-forth via email on the design, Grondin had eight designs he started with for the Boston shortstop. “Bogaerts is a flashy player and we have reds and blues across the board, which gives us more flexibility,” he says. “He bit on the all-white with a red saddle and navy laces. I was pumped to see that.”

Bogaerts started wearing the custom cleat the last week in August at home. “It was the white man, the white and red with our uniforms,” Bogaerts tells SI.com about why he picked out the one he did before discussing having a new road design customized.

Cano was a little more subdued in his debut cleat, going heavily black with hints of the teal blue from the Mariners.

Even across the 50-step build of the cleat, New Balance locked together a few components of the cleat, such as the heel and front saddle and the new comfort collar. “While we want freedom for the consumer to do what they want,” Grondin says, “we want it to look great and look like a premium product.”

The new 3000v3 comes together with 14 different workers in the Lawrence facility hand stitching and using custom-made machines to piece together the 50 individual steps in building the cleat. Coming in a choice of mid-top or low top, customization also includes a black-and-white metal spike, black-and-white molded TPU spike or gold metal spike plate. Customers can also choose between mesh and suede with other options rotating seasonally.

New Balance, which has customized lifestyle lines—the 574, 998 and 990—in Lawrence since 2011, had to get a bit more complex with the performance product. Each cleat takes about 68 minutes to build on the production line, with 12 color options for each of the 16 customizable areas.

Dave Millman, strategic manager for New Balance baseball, says that customization had been a request from youth players to the professionals for years. New Balance, which has 450 professional players wearing cleats from the minors through the majors, used data from its players—such as Jose Bautista and Boston’s Dustin Pedroia, the company’s first baseball athlete—to help design the new cleat with a 3D foam-molded 360-degree collar for additional comfort and protection around the ankle. Millman calls the cleat a running shoe on spikes.

With U.S.-made customization part of the New Balance cleat process, expect to see athletes of all ages channeling their Bogaerts-influenced design choices and personalizing their own cleat style.

Tim Newcomb covers sports aesthetics—stadiums to sneakers—and training for Sports Illustrated. Follow him on Twitter on @tdnewcomb.