Nike reveals the secret behind Kyrie Irving, Kevin Durant sneaker traction

Your teams. Your favorite writers. Wherever you want them. Personalize SI with our new App. Install on iOS or Android.

The value of the herring fish for basketball sneakers can’t be understated. The herringbone pattern—so named for the bones of this foraging fish found in northern waters—has turned into the most prominent and well-respected way to gain traction on the polished maple floors of today’s basketball arenas.

But the herringbone didn’t always reign supreme, and it hasn’t gone without a modern makeover.

The canvas and rubber shoes of yesteryear offered a mix of traction, both horizontal lines and a diamond pattern, as found in Converse’s Chuck Taylor. But by the 1980s, Nike in particular, was experimenting with new ways to grab the court, whether an indoor or outdoor surface. As they investigated traction, they found the need to take into account surface type, surface ratio and rubber composition.

• Conley rare trustworthy guard in free agency | Top 50 free agents

While the Nike Air Raid, for example, features a loose zigzagging pattern for outdoor use—the rough pavements and blacktops of the outdoor game requires less grooving from the sneaker to maintain the proper surface ratio—building traction for the indoor game and specifically quality maple floors became more intricate. Traction patterns on the well-worn Air Force 1 and Nike Dunk designs from the 1980s featured concentric circles on the forefoot to allow players to pivot and rotate while maintaining grip. While concentric circles haven’t evaporated, they’ve been joined with the herringbone pattern.

“Herringbone always works traditionally really well,” Eric Avar, a key Nike shoe designer and creator of the Kobe line, tells SI.com. The pattern, which basically stacks diagonal grooves up and down across a horizontal plane, responds well to the multidirectional footwork in basketball, Avar says, the optimal pattern for the footwork biomechanics of the game.

Experts say half of a shoe’s outsole surface area should remain in contact with the court at any given time for prime traction. When designing and evaluating a shoe’s traction pattern and its contact with the court surface, it’s important to factor in three elements: impact, biomechanics and multidirectional movement.

While accelerating, the front third of a shoe’s outsole may be in contact with the court with the midfoot and heel off court. With this movement in mind, pinpoint precision for each region of the outsole must be factored in while looking at the ratio of contact between the rubber and court.

And then there’s the rubber, which gets heated to an exact temperature over a precise timeframe. The baking process dictates the rubber’s touch or firmness. The longer it’s heated, the harder the material, meaning the tacky grip of an outsole can get tuned based on the heating process.

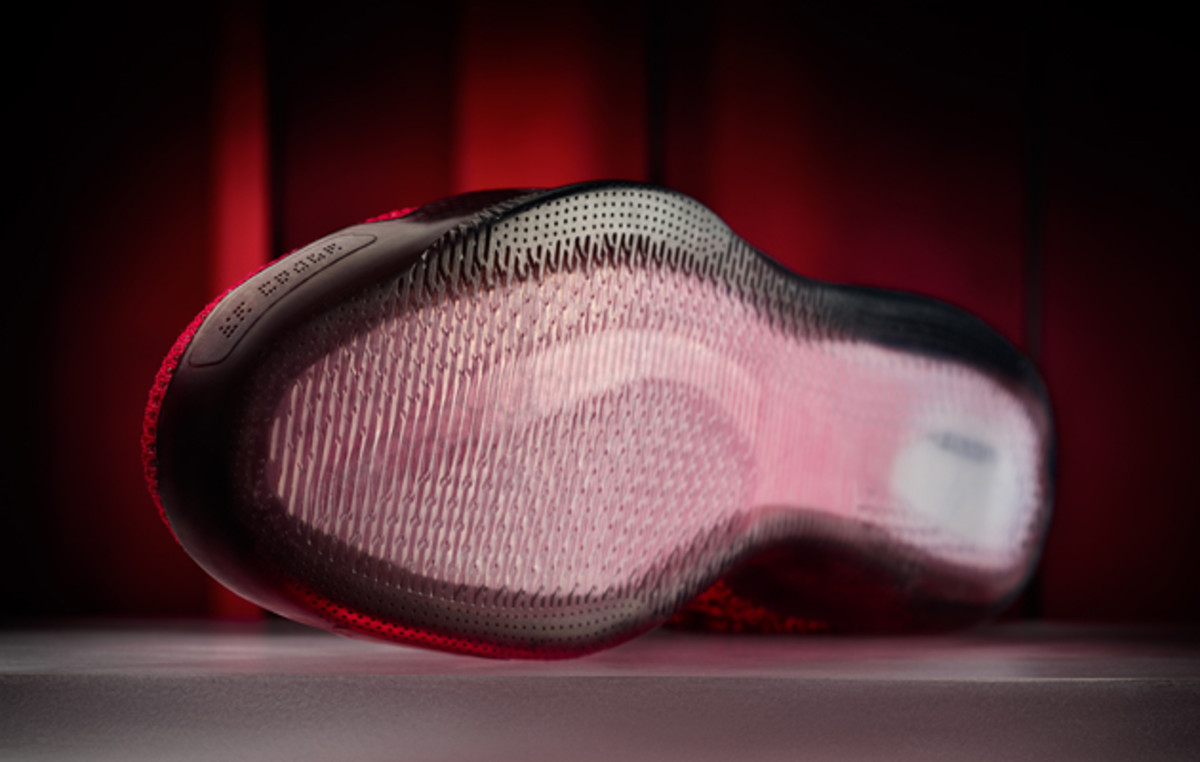

Modern engineering has allowed for a tweaking of this tuning. The Kobe X, released in 2015, really showed this process as Avar and Kobe Bryant worked together to create a new traction based off herringbone that added hundreds of tiny “nodules,” which were so grippy during the testing process they had to dial back the grip.

• LeBron opts out of contract | Team USA, Nike unveil Rio gear

“We wanted to create a similar feel and geometry (to herringbone), but in a new way that worked in conjunction with the midsole,” Avar says. “By breaking up and having so many nodules, it bit and gripped into the hardwood.”

Avar extended what he started in the Kobe X into the Kobe 11, using the nodules for traction in an outsole that splays when the foot compresses, allowing flex grooves to open up and put different parts of the tread in contact with the floor as needed.

Herringbone sometimes can handle a little creativity, though, whether for style or function. Whether the Air Jordan IX, released in 1993, that featured an intricate inspiration of dates and symbols meaningful to Michael Jordan, or the 2014-released Kyrie 1 with the letter H embedded in both the left and right outsoles to tie to Irving’s favorite motto, “Hungry and Humble,” designers have long toyed with the creativity of a modified herringbone pattern.

Leo Chang, designer of the Nike Kyrie models, Kevin Durant’s signature line and the Hyperdunk, tells SI.com that while you must make the science of traction work, there’s a need to visually separate the aesthetics from other shoes and other athletes to make it unique. There are those non-friction points on the outsole that allow for that creativity.

But creativity never gets in the way of that perfect court friction. “Traction is your first point of contact for a player,” he says. “If (players) aren’t confident with the traction, they are going to play more reserved and more tentative.”

• Whiteside will be hot commodity | Team USA roster no Dream Team

Chang took a herringbone-inspired design beyond the outsole when designing both the Kyrie 1 and Kyrie 2. He built the outsole traction up the sidewall of the shoe since Irving spends so much time in low angles with the sides of his shoes engaged with the floor. Chang also introduced a curved bottom surface of the midsole and outsole. The rounded geometry positioned at the medial heel and across the metatarsals heads allow Irving to redistribute weight without slapping his foot on the court. “It’s almost as if your body weight is bouncing off a ball,” Chang says. To go with this new outsole design, Nike changed up the traction pattern around the curved periphery, offering extra grip for lateral movement.

“When I saw the way (Kyrie) played, there is no way I couldn’t consider a different solution for him,” Chang says.

While the Kyrie 1 featured a modified herringbone pattern, the Kyrie 2 experimented with pattern even more by taking into account curvature and the need for traction on the side of the foot.

Even as Chang embraced the circular pattern on the Kyrie shoe under the ball of the foot because “it works really well for multidirectional movement,” the oval on the Kyrie 2 has progressed far beyond the Air Force 1. The traction has become thinner and lighter, all based on lab and video testing, along with athlete perceptive tests, giving designers the knowledge of how much traction is too much and when it isn’t enough.

On the brand-new KD9 sneaker, Chang embraced the herringbone, but not so obviously. The pattern looks like a basic honeycomb pattern, but “tuning” for cuts right and left, running and breaking all forced him to rework the pattern on a micro level.

“There is a certain amount of material you need to get the right amount of friction on the court,” Chang says. “It is about a percentage you want to get right.” Added in with the proper rubber compound and pattern geometry and traction has married science, even if the discussion always goes back to the herringbone.

“It is the go-to traction pattern,” Chang says. “We are always trying to one-up herringbone.”

Tim Newcomb covers sports aesthetics—stadiums to sneakers—and training for Sports Illustrated. Follow him on Twitter at @tdnewcomb.